Nissan Rogue Service Manual: Drive belts

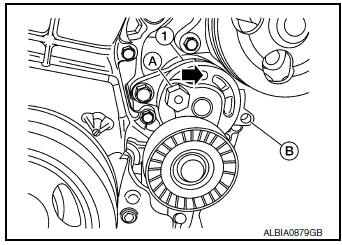

Exploded view

- Generator pulley

- Water pump pulley

- Drive belt auto-tensioner

- Crankshaft pulley

- A/C compressor pulley

- Drive belt retainer boss

- View A

- New drive belt range

- Possible use range

- Indicator (notch)

Checking

WARNING: Inspect the drive belt only when the engine is stopped.

- Visually check entire drive belt for wear, damage or cracks.

- Check that the drive belt auto-tensioner indicator is within the possible use range.

NOTE:

- When new drive belt is installed, the drive belt auto-tensioner indicator should be within the new drive belt range.

- Check the drive belt auto-tensioner indicator when the engine is cold.

- If the drive belt auto-tensioner indicator is out of the possible use range or belt is damaged, replace drive belt.

Tension adjustment

Belt tension is not manually adjustable. It is automatically adjusted by the drive belt auto-tensioner.

Removal and installation

REMOVAL

- Remove wheel and tire (RH) using a power tool.

- Remove engine under cover. Refer to EXT-37, "ENGINE UNDER COVER : Removal and Installation"

- Remove fender protector side cover. Refer to EXT-28, "FENDER PROTECTOR : Exploded View".

- Securely hold the hexagonal part (A) of drive belt auto-tensioner (1) using suitable tool, and move in the direction of arrow (loosening direction of tensioner).

- Insert a rod approximately 6 mm (0.24 in) in diameter through the rear of the drive belt auto-tensioner into retaining boss (B) to lock drive belt auto-tensioner pulley.

WARNING: Avoid placing hand in a location where pinching may occur if the holding tool accidentally comes off.

NOTE: Leave drive belt auto-tensioner pulley arm locked until drive belt is installed again.

- Loosen drive belt from drive belt auto-tensioner and then remove it from the other pulleys.

- Installation of remaining components is in the reverse order of removal.

INSTALLATION

Installation is in the reverse order of removal.

- Install the drive belt onto all of the pulleys except for the drive belt auto-tensioner. Then install the drive belt onto drive belt auto-tensioner last.

CAUTION:

- Confirm belts are completely set on the pulleys.

- Check for engine oil and engine coolant. Be sure they are not adhered to the drive belt and each pulley groove.

- Release the drive belt auto-tensioner and apply tension to drive belt.

WARNING: Avoid placing hand in a location where pinching may occur if the holding tool accidentally comes off.

- Turn crankshaft pulley clockwise several times to equalize tension between each pulley.

- Confirm the indicator is within the possible use range. Refer to EM-13, "Checking"

- Install wheel and tire (RH). Refer to WT-57, "Adjustment".

Removal and installation of drive belt auto-tensioner

- Drive belt auto-tensioner

REMOVAL

CAUTION: The complete drive belt auto-tensioner must be replaced as a unit, including the pulley.

- Remove the drive belt. Refer to EM-13, "Removal and Installation".

- Remove the drive belt auto-tensioner.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION: Install the drive belt auto-tensioner carefully so not to damage the water pump pulley.

Air cleaner filter

Air cleaner filter

Exploded view

Mass air flow sensor

Air cleaner filter

Air cleaner case (lower)

Air duct assembly

Grommet

Resonator bracket (front)

Resonator bracket (rear)

...

Other materials:

U1000 CAN COMM circuit

Description

CAN (Controller Area Network) is a serial communication system for real time

application. It is an on-vehicle

multiplex communication system with high data communication speed and excellent

error detection ability.

Many electronic control units are equipped into vehicles, and ea ...

Brake fluid

Drain and Refill

CAUTION:

Do not spill or splash brake fluid on painted surfaces. Brake

fluid may damage paint. If brake fluid is

splashed on painted areas, wash it away with water immediately.

Prior to repair, turn the ignition switch OFF, disconnect the

ABS actuator and ...

Front disc brake

BRAKE PAD

BRAKE PAD : Inspection

Check brake pad wear thickness from an inspection hole (A) on cylinder

body. Check using a scale if necessary.

Wear thickness : Refer to BR-55, "Front Disc Brake".

DISC BRAKE ROTOR

DISC BRAKE ROTOR : Inspection

APPEARANCE

Check surface of disc b ...