Nissan Rogue Service Manual: Electrical load signal

Description

The electrical load signal (Headlamp switch signal, rear window defogger switch signal, etc.) is transferred via the CAN communication.

Component Function Check

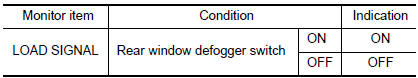

1.CHECK REAR WINDOW DEFOGGER SWITCH FUNCTION

- Turn ignition switch ON.

- Connect CONSULT and select ÔÇťDATA MONITORÔÇŁ mode.

- Select ÔÇťLOAD SIGNALÔÇŁ and check indication under the following conditions.

Is the inspection result normal? YES >> GO TO 2.

NO >> Proceed to EC-462, "Diagnosis Procedure".

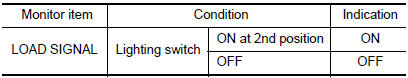

2.CHECK LIGHTING SWITCH FUNCTION

Check ÔÇťLOAD SIGNALÔÇŁ indication under the following conditions.

Is the inspection result normal? YES >> GO TO 3.

NO >> Proceed to EC-462, "Diagnosis Procedure".

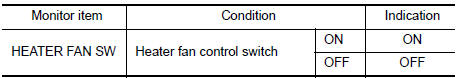

3.CHECK HEATER FAN CONTROL SWITCH FUNCTION

Select ÔÇťHEATER FAN SWÔÇŁ and check indication under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-462, "Diagnosis Procedure".

Diagnosis Procedure

1.INSPECTION START

Confirm the malfunctioning circuit (rear window defogger, headlamp or heater fan). Refer to EC-462, "Component Function Check".

Which circuit is related to the incident? Rear window defogger>>GO TO 2.

Headlamp>>GO TO 3.

Heater fan>>GO TO 4.

2.CHECK REAR WINDOW DEFOGGER SYSTEM

Check rear window defogger system. Refer to DEF-19, "Work Flow".

>> INSPECTION END

3.CHECK HEADLAMP SYSTEM

Check headlamp system. Refer to EXL-82, "Work Flow" (with halogen headlamp) or EXL-219, "Work Flow" (with LED headlamp).

>> INSPECTION END

4.CHECK HEATER FAN CONTROL SYSTEM

Check heater fan control system. Refer to HAC-46, "Work Flow" (with automatic air conditioner) or HAC-146, "Work Flow" (with manual air conditioner).

>> INSPECTION END

Cooling fan

Cooling fan

Component Function Check

1.CHECK COOLING FAN FUNCTION

With CONSULT

Turn ignition switch ON.

Perform ÔÇťCOOLING FAN (DUAL)ÔÇŁ in ÔÇťACTIVE TESTÔÇŁ mode of ÔÇťIPDM E/RÔÇŁ

using CO ...

Fuel injector

Fuel injector

Component Function Check

1.INSPECTION START

Turn ignition switch to START.

Are any cylinders ignited?

YES >> GO TO 2.

NO >> Proceed to EC-464, "Diagnosis Procedure".

2. ...

Other materials:

Diagnosis and repair work flow

Work Flow

DETAILED FLOW

1.INTERVIEW FROM THE CUSTOMER

Clarify customer complaints before inspection. First of all, perform an

interview utilizing BRC-67, "Diagnostic

Work Sheet" and reproduce the symptom as well as fully understand it. Ask

customer about his/her complaints

careful ...

System description

COMPONENT PARTS

Component Parts Location

No.

Component

Description

1

Push-button ignition

switch1

Push-button ignition switch (push switch) is pressed (ON), and

transmits status signal to BCM

and IPDM E/R.

Ignition switch2

Ignition ...

Filament

Inspection and Repair

INSPECTION

When measuring voltage, wrap tin foil around the top of the

negative

probe. Then press the foil against the wire with your finger.

Attach probe circuit tester (in Volt range) to middle portion of

each filament.

If a filament is b ...