Nissan Rogue Service Manual: Radiator

RADIATOR CAP

RADIATOR CAP : Inspection

CHECKING RADIATOR CAP

- Inspect the radiator cap.

- Replace the cap if the metal plunger cannot be seen around the edge of the black rubber gasket.

- Replace the cap if deposits of waxy residue or other foreign material are on the black rubber gasket or the metal retainer.

NOTE: Thoroughly wipe out the radiator filler neck to remove any waxy residue or foreign material.

- Pull the negative-pressure valve to open it and check that it closes completely when released.

- Check that there is no dirt or damage on the valve seat of the radiator cap negative-pressure valve.

- Check that there are no abnormalities in the opening and closing conditions of the negative-pressure valve.

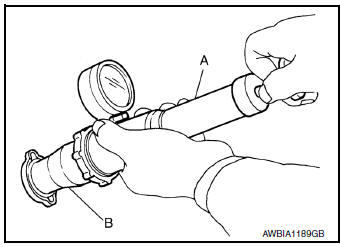

- Check radiator cap relief pressure using suitable tool (A/B).

Standard : Refer to CO-25, "Radiator"

- Apply water or engine coolant to the cap seal surface before connecting the radiator cap to the tester.

- Replace the radiator cap if there is an abnormality in the negative- pressure valve, or if the open-valve pressure is outside of the standard values.

RADIATOR

RADIATOR : Inspection

Check radiator for mud or clogging. If necessary, clean radiator as follows.

CAUTION:

- Be careful not to bend or damage radiator fins.

- When radiator is cleaned without removal, remove all surrounding parts such as radiator cooling fan assembly and horns. Then tape harness and harness connectors to prevent water from entering.

- Spray water to the back side of the radiator core using a side to side motion from the top down.

- Stop spraying when debris no longer flows from radiator core.

- Blow air into the back side of radiator core using a side to side motion from the top down.

- Use compressed air lower than 490 kPa (5 kg/cm2, 71 psi) and keep distance more than 30 cm (11.8 in).

- Continue to blow air until no water sprays out.

- Check for engine coolant leaks. Repair as necessary.

Engine coolant

Engine coolant

Inspection

LEVEL

Check that the reservoir tank engine coolant level is within the

“MIN” to “MAX” when the engine is cool.

(A) : MAX

(B) : MIN

Adjust the engine coolant l ...

Other materials:

Service data and specifications (sds)

Idle Speed

Condition

Specification

No load* (in P or N position)

650 ± 50 rpm

*: Under the following conditions

A/C switch: OFF

Electric load: OFF (Lights, heater fan & rear window defogger)

Steering wheel: Kept in straight-ahead position

...

NISSAN vehicle immobilizer system

The NISSAN Vehicle Immobilizer System will not

allow the engine to start without the use of a

registered key.

Never leave these keys in the vehicle.

FCC Notice:

For USA:

This device complies with part 15 of the

FCC Rules. Operation is subject to the following

two conditions: (1) This device ...

Removal and installation

FRONT AIR CONTROL

Removal and Installation

REMOVAL

Release the front air control clips and pawls using a suitable

tool.

: Metal clip

: Pawl

Disconnect the harness connector from the front air control (1)

and remove.

INSTALLATION

Installation is in the reverse order of ...