Nissan Rogue Service Manual: P2096, P2097 A/F sensor 1

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition |

| P2096 | POST CATALYST FUEL TRIM SYS B1 (Post catalyst fuel trim system too lean bank 1) | The output voltage computed by ECM from the A/F sensor 1 signal is shifts to the lean side for a specified period. |

| P2097 | POST CATALYST FUEL TRIM SYS B1 (Post catalyst fuel trim system too rich bank 1) | The A/F signal computed by ECM from the A/F sensor 1 signal is shifts to the rich side for a specified period. |

POSSIBLE CAUSE

- A/F sensor 1

- A/F sensor 1 heater

- Heated oxygen sensor 2

- Fuel pressure

- Fuel injector

- Intake air leaks

- Exhaust gas leaks

FAIL-SAFE

Not applicable

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait least 10 seconds.

TESTING CONDITION: Before performing the following procedure, confirm that battery voltage is more than 11 at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Clear the mixture ratio self-learning value. Refer to EC-143, "Work Procedure"

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and keep the engine speed between 3,500 and 4,000 rpm for 1 minute under no load.

- Let engine idle for 1 minute.

- Keep engine speed between 2,500 and 3,000 rpm for 20 minutes.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-426, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK HARNESS CONNECTOR

- Turn ignition switch OFF.

- Disconnect A/F sensor 1 harness connector.

- Check harness connector for water.

Water should not exit.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace harness connector.

2.RETIGHTEN A/F SENSOR 1 AND HEATED OXYGEN SENSOR 2

Loosen and retighten the A/F sensor 1 and heated oxygen sensor 2. Refer to EM-29, "Exploded View", EX-5, "Exploded View".

>> GO TO 3.

3.CHECK FOR EXHAUST GAS LEAK

- Start engine and run it at idle.

- Listen for an exhaust gas leak before the three way catalyst 2.

Is exhaust gas leak detected? YES >> Repair or replace malfunctioning parts.

NO >> GO TO 4.

4.CHECK FOR INTAKE AIR LEAK

- Reconnect A/F sensor 1 harness connector.

- Start engine and run it at idle.

- Listen for an intake air leak after the mass air flow sensor.

Is intake air leak detected? YES >> Repair or replace malfunctioning parts.

NO >> GO TO 5.

5.CLEAR THE MIXTURE RATIO SELF-LEARNING VALUE

- Clear the mixture ratio self-learning value. Refer to EC-143, "Work Procedure".

- Run engine for at least 10 minutes at idle speed.

Is the 1st trip DTC P0171 or P0172 detected? Is it difficult to start engine? YES >> Perform trouble diagnosis for DTC P0171 or P0172. Refer to EC-260, "DTC Description" or EC- 265, "DTC Description".

NO >> GO TO 6.

6.CHECK A/F SENSOR 1 POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect A/F sensor 1 harness connector.

- Turn ignition switch ON.

- Check the voltage between A/F sensor 1 harness connector and ground.

Is the inspection result normal? YES >> GO TO 8.

NO >> GO TO 7.

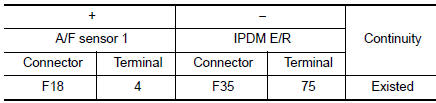

7.CHECK A/F SENSOR 1 POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect IPDM E/R harness connector.

- Check the continuity between A/F sensor 1 harness connector and IPDM E/R harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

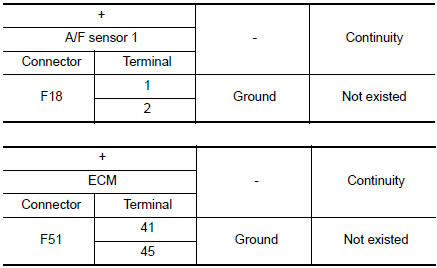

8.CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between A/F sensor 1 harness connector and ECM harness connector.

- Check the continuity between A/F sensor 1 harness connector and ground, or ECM harness connector and ground.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 9.

NO >> Repair or replace error-detected parts.

9.CHECK A/F SENSOR 1 HEATER

Check the A/F sensor 1 heater. Refer to EC-186, "Component Inspection".

Is the inspection result normal? YES >> GO TO 10.

NO >> GO TO 12.

10.CHECK HEATED OXYGEN SENSOR 2

Check heated oxygen sensor 2. Refer to EC-239, "Component Inspection".

Is the inspection result normal? YES >> GO TO 11.

NO >> Replace heated oxygen sensor 2. Refer to EX-5, "Exploded View".

11.CHECK INTERMITTENT INCIDENT

Perform GI-41, "Intermittent Incident".

Is the inspection result normal? YES >> GO TO 12.

NO >> Repair or replace error-detected parts.

12.REPLACE AIR FUEL RATIO (A/F) SENSOR 1

Replace air fuel ratio (A/F) sensor 1. Refer to EM-29, "Exploded View".

CAUTION:

- Discard any sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a hard surface such as a concrete floor; use a new one.

- Before installing new sensor, clean exhaust system threads using Oxygen Sensor Thread Cleaner [commercial service tool (J-43897-18 or J-43897-12)] and approved Anti-seize Lubricant (commercial service tool).

Do you have CONSULT? YES >> GO TO 13.

NO >> GO TO 14.

13.CONFIRM A/F ADJUSTMENT DATA

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select “A/F ADJ-B1” in “DATA MONITOR” mode of “ENGINE” using CONSULT.

- Make sure that “0.000” is displayed on CONSULT screen.

Is “0.000” displayed? YES >> INSPECTION END

NO >> GO TO 14.

14.CLEAR THE MIXTURE RATIO SELF-LEARNING VALUE

Clear the mixture ratio self-learning value. Refer to EC-143, "Work Procedure".

Do you have CONSULT? YES >> GO TO 15.

NO >> INSPECTION END

15.CONFIRM A/F ADJUSTMENT DATA

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select “A/F ADJ-B1” in “DATA MONITOR” mode of “ENGINE” using CONSULT.

- Make sure that “0.000” is displayed on CONSULT screen.

>> INSPECTION END

P2014, P2016, P2017, P2018 intake manifold runner control

valve position sensor

P2014, P2016, P2017, P2018 intake manifold runner control

valve position sensor

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P2014

IN/MANIFOLD RUNNER POS SEN B1

(Intake manifo ...

P2100, P2103 throttle control motor relay

P2100, P2103 throttle control motor relay

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P2100

ETC MOT PWR-B1

(Throttle actuator ″A&# ...

Other materials:

P0963 pressure control solenoid A

DTC Description

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P0963

PC SOLENOID A(Pressure Control Solenoid A Control Circuit

High)

When all of the following conditions are satisfied and this state is

maintain ...

U1111 lost communication (chassis control module)

DTC Description

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

U1111

LOST COMM (CHASSIS CONT MDUL)

(Lost Communication With Chassis Control

Module)

When the ignition switch is ON, TCM is unable to receive the CA ...

Combination meter

Removal and Installation

REMOVAL

Disconnect the negative battery terminal. Refer to PG-77, "Removal

and Installation".

Remove the cluster lid A. Refer to IP-20, "Removal and

Installation".

Remove screws (A), from the combination meter (1).

...