Nissan Rogue Service Manual: DTC/circuit diagnosis

P1610 LOCK MODE

Description

ECM forcibly switches to the mode that inhibits engine start, when engine start operation is performed 5 times or more while communication between ECM and BCM is not normal.

DTC Logic

DTC DETECTION LOGIC

NOTE:

- If DTC B1610 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to DLK-104, "DTC Logic".

- If DTC B1610 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to DLK-105, "DTC Logic".

|

DTC No. |

Trouble diagnosis name |

DTC detecting condition |

Possible cause |

| P1610 | LOCK MODE | When ECM detects a communication malfunction between ECM and BCM 5 times or more. |

тАФ |

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch ON.

- Check DTC in тАЬSelf-Diagnostic ResultтАЭ mode of тАЬENGINEтАЭ using CONSULT.

Is DTC detected? YES >> Go to SEC-155, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

1.CHECK ENGINE START FUNCTION

- Check that there are no DTCтАЩs except for DTC P1610 detected.

If detected, erase the DTC after fixing.

- Turn ignition switch OFF.

- Insert the registered key into the ignition switch and wait 5 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait 5 seconds.

- Repeat steps 3 and 5 twice (a total of 3 times).

- Check that engine can start.

>> Inspection End.

P1611 ID DISCORD, IMMU-ECM

DTC Logic

DTC DETECTION LOGIC

|

DTC No. |

Trouble diagnosis name |

DTC detecting condition |

Possible cause |

| P1611 | ID DISCORD, IMMU-ECM | The ID verification results between BCM and ECM are NG. |

|

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch ON.

- Check DTC in тАЬSelf-Diagnostic ResultтАЭ mode of тАЬENGINEтАЭ using CONSULT.

Is DTC detected? YES >> Go to SEC-156, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

1.PERFORM INITIALIZATION

Perform initialization of BCM and reregistration of all keys using CONSULT. Refer to the CONSULT Immobilizer mode and follow the on-screen instructions.

Can the system be initialized and can the engine be started with reregistered key? YES >> Inspection End.

NO >> GO TO 2.

2.CHECK SELF DIAGNOSTIC RESULT

- Select тАЬSelf Diagnostic ResultтАЭ mode of тАЬENGINEтАЭ using CONSULT.

- Erase DTC.

- Perform DTC CONFIRMATION PROCEDURE for DTC P1611. Refer to SEC-156, "DTC Logic".

Is DTC detected? YES >> GO TO 3.

NO >> Inspection End.

3.REPLACE BCM

- Replace BCM. Refer to BCS-135, "Removal and Installation".

- Perform initialization of BCM and registration of all keys using CONSULT. Refer to the CONSULT Immobilizer mode and follow the on-screen instructions.

Can the system be initialized and can the engine be started with registered key? YES >> Inspection End.

NO >> GO TO 4.

4.REPLACE ECM

- Replace ECM. Refer to EC-499, "Removal and Installation".

- Perform тАЬADDITIONAL SERVICE WHEN REPLACING ECMтАЭ. Refer to EC-136, "Work Procedure".

>> Inspection End.

P1612 CHAIN OF ECM-IMMU

DTC Logic

DTC DETECTION LOGIC

NOTE:

- If DTC P1612 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to DLK-104, "DTC Logic".

- If DTC P1612 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to DLK-105, "DTC Logic".

|

DTC No. |

Trouble diagnosis name |

DTC detecting condition |

Possible cause |

| P1612 | CHAIN OF BCM-ECM | Inactive communication between BCM and ECM |

|

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch ON.

- Check DTC in тАЬSelf-Diagnostic ResultтАЭ mode of тАЬBCMтАЭ using CONSULT.

Is DTC detected? YES >> Go to SEC-157, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

NOTE:

- If DTC P1612 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to DLK-104, "DTC Logic".

- If DTC P1612 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to DLK-105, "DTC Logic".

1.CHECK BCM POWER SUPPLY AND GROUND CIRCUIT.

Check BCM power supply and ground circuit. Refer to BCS-128, "Diagnosis Procedure".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace the harness.

2.CHECK ECM POWER SUPPLY AND GROUND CIRCUIT.

Check ECM power supply and ground circuit. Refer to EC-165, "Diagnosis Procedure".

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace the harness.

3.PERFORM DTC CONFIRMATION PROCEDURE.

Perform the DTC confirmation procedure. Refer to SEC-157, "DTC Logic".

Does the DTC return? YES >> Replace BCM. Refer to BCS-135, "Removal and Installation" NO >> Inspection End.

P161D IMMOBILIZER

DTC Logic

DTC DETECTION LOGIC

|

DTC No. |

Trouble diagnosis name |

DTC detecting condition |

Possible cause |

| P161D | IMMOBILIZER | When immobilizer detects a malfunction, and prohibits the engine start. | BCM |

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch ON.

- Check DTC in тАЬSelf Diagnostic ResultтАЭ mode of тАЬENGINEтАЭ using CONSULT.

Is DTC detected? YES >> Refer to SEC-160, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

1.REPLACE BCM

Replace BCM. Refer to BCS-135, "Removal and Installation".

>> Inspection End.

P161E IMMOBILIZER

DTC Logic

DTC DETECTION LOGIC

|

DTC No. |

Trouble diagnosis name |

DTC detecting condition |

Possible cause |

| P161E | IMMOBILIZER | After replacing the ECM, when the ECM is not registered to the vehicle by using the CONSULT. |

|

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch ON.

- Check DTC in тАЬSelf Diagnostic ResultтАЭ mode of тАЬENGINEтАЭ using CONSULT.

Is DTC detected? YES >> Refer to SEC-160, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

1.PERFORM REGISTRATION OF ECM

Perform registration of ECM using CONSULT.

Is DTC detected? YES >> Inspection End.

NO >> GO TO 2.

2.REPLACE BCM

Replace BCM. Refer to BCS-135, "Removal and Installation".

Is DTC detected? YES >> GO TO 3.

NO >> Inspection End.

3.REPLACE ECM

Replace ECM. Refer to EC-499, "Removal and Installation".

>> Inspection End.

P161F IMMOBILIZER

DTC Logic

DTC DETECTION LOGIC

|

DTC No. |

Trouble diagnosis name |

DTC detecting condition |

Possible cause |

| P161F | MMOBILIZER | When immobilizer detects a malfunction, and prohibits the engine start. | ECM |

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch ON.

- Check DTC in тАЬSelf Diagnostic ResultтАЭ mode of тАЬENGINEтАЭ using CONSULT.

Is DTC detected? YES >> Refer to SEC-160, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

1.REPLACE ECM

Replace ECM. Refer to EC-499, "Removal and Installation".

>> Inspection End.

B20DF STARTER RELAY OFF CIRCUIT

DTC Logic

DTC DETECTION LOGIC

NOTE:

- If DTC B20DF is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to BCS-124, "DTC Logic".

- If DTC B20DF is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to BCS-125, "DTC Logic".

|

DTC No. |

Trouble diagnosis name |

DTC detecting condition |

Possible cause |

| B20DF | STARTER RELAY OFF | When comparing the starter relay signal (CAN) from BCM, IPDM E/R detects that starter relay is stuck in the OFF position for 1 second or more. |

|

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch under the following conditions to start

engine, and wait 1 second or more.

- Selector lever: In the P position

- Check DTC in "Self Diagnostic Result" mode of "BCM" using CONSULT.

Is DTC detected? YES >> Go to SEC-161, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to SEC-127, "Wiring Diagram".

1.CHECK STARTER RELAY POWER SUPPLY CIRCUIT (SWITCH SIDE)

- Turn ignition switch ON.

- Brake pedal pressed.

- Place transmission in park or neutral.

- Check voltage between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> Refer to SEC-90, "Diagnosis Procedure".

2.CHECK STARTER RELAY POWER SUPPLY CIRCUIT (COIL SIDE)

- Turn ignition switch ON.

- Place transmission in park or neutral.

- Check voltage between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> Replace IPDM E/R. Refer to PCS-35, "Removal and Installation".

NO >> Refer to SEC-82, "Diagnosis Procedure".

B2192 ID DISCORD, IMMU-ECM

DTC Logic

DTC DETECTION LOGIC

|

DTC No. |

Trouble diagnosis name |

DTC detecting condition |

Possible cause |

| B2192 | ID DISCORD BCM-ECM | The ID verification results between BCM and ECM are NG. |

|

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch ON.

- Check DTC in тАЬSelf-Diagnostic ResultтАЭ mode of тАЬBCMтАЭ using CONSULT.

Is DTC detected? YES >> GO TO SEC-163, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

1.PERFORM INITIALIZATION

Perform initialization of BCM and reregistration of all keys using CONSULT. Refer to the CONSULT Immobilizer mode and follow the on-screen instructions.

Can the system be initialized and can the engine be started with reregistered key? YES >> Inspection End.

NO >> GO TO 2.

2.CHECK SELF-DIAGNOSTIC RESULT

- Select тАЬSelf Diagnostic ResultтАЭ mode of тАЬBCMтАЭ using CONSULT.

- Erase DTC.

- Perform DTC CONFIRMATION PROCEDURE for DTC B2192. Refer to SEC-163, "DTC Logic".

Is DTC detected? YES >> GO TO 3.

NO >> Inspection End.

3.REPLACE BCM

- Replace BCM. Refer to BCS-135, "Removal and Installation".

- Perform initialization of BCM and reregistration of all keys using CONSULT. Refer to the CONSULT Immobilizer mode and follow the on-screen instructions.

Can the system be initialized and can the engine be started with registered key? YES >> Inspection End.

NO >> GO TO 4.

4.REPLACE ECM

- Replace ECM. Refer to EC-499, "Removal and Installation".

- Perform тАЬADDITIONAL SERVICE WHEN REPLACING ECMтАЭ. Refer to EC-136, "Work Procedure".

>> Inspection End.

B2193 CHAIN OF ECM-IMMU

DTC Logic

DTC DETECTION LOGIC

NOTE:

- If DTC B2193 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to BCS-124, "DTC Logic".

- If DTC B2193 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to BCS-125, "DTC Logic".

|

DTC No. |

Trouble diagnosis name |

DTC detecting condition |

Possible cause |

| B2193 | CHAIN OF BCM-ECM | Inactive communication between BCM and ECM |

|

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch ON.

- Check DTC in тАЬSelf-Diagnostic ResultтАЭ mode of тАЬBCMтАЭ using CONSULT.

Is DTC detected? YES >> GO TO SEC-164, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

NOTE:

- If DTC B2193 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to BCS-124, "DTC Logic".

- If DTC B2193 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to BCS-125, "DTC Logic".

1.CHECK BCM POWER SUPPLY AND GROUND CIRCUIT.

Check BCM power supply and ground circuit. Refer to BCS-128, "Diagnosis Procedure".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace the harness.

2.CHECK ECM POWER SUPPLY AND GROUND CIRCUIT.

Check ECM power supply and ground circuit. Refer to EC-165, "Diagnosis Procedure".

Is the inspection result normal? YES >> Replace ECM. Refer toEC-499, "Removal and Installation". GO TO 3.

NO >> Repair or replace the harness.

3.PERFORM DTC CONFIRMATION PROCEDURE.

Perform the DTC confirmation procedure. Refer to SEC-164, "DTC Logic".

Does the DTC return? YES >> Replace BCM. Refer to BCS-135, "Removal and Installation" NO >> Inspection End.

B2196 DONGLE UNIT

Description

BCM performs ID verification between BCM and dongle unit.

When verification result is OK, BCM permits cranking.

DTC Logic

DTC DETECTION LOGIC

NOTE:

- If DTC B2196 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to BCS-124, "DTC Logic".

- If DTC B2196 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to BCS-125, "DTC Logic".

|

DTC No. |

Trouble diagnosis name |

DTC detecting condition |

Possible cause |

| B2196 | DONGLE NG | The ID verification results between BCM and dongle unit is NG. |

|

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch ON.

- Turn ignition switch OFF.

- Turn ignition switch ON.

- Check тАЬSelf-diagnostic resultтАЭ of "BCM" using CONSULT.

Is the DTC detected? YES >> Refer to SEC-165, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to SEC-127, "Wiring Diagram".

1.PERFORM INITIALIZATION

- Perform initialization of BCM and reregistration of all keys using CONSULT. Refer to the CONSULT Immobilizer mode and follow the on-screen instructions.

- Start the engine.

Dose the engine start? YES >> Inspection End.

NO >> GO TO 2.

2.CHECK DONGLE UNIT CIRCUIT

- Turn ignition switch OFF.

- Disconnect BCM connector and dongle unit connector.

- Check continuity between BCM harness connector and dongle unit harness connector.

- Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK DONGLE UNIT GROUND CIRCUIT

Check continuity between dongle unit harness connector and ground.

Is the inspection result normal? YES >> Replace dongle unit.

NO >> Repair or replace harness.

B2198 NATS ANTENNA AMP.

DTC Logic

DTC DETECTION LOGIC

|

DTC No. |

Trouble diagnosis name |

DTC detecting condition |

Possible cause |

| B2198 | NATS ANTENNA AMP | Inactive communication between NATS antenna amp. and BCM is detected when BCM enters in the low power consumption mode (BCM sleep condition) |

|

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

- Make the conditions that BCM enters in the low power consumption

mode (BCM sleep condition).

Refer to BCS-84, "POWER CONSUMPTION CONTROL SYSTEM : System Description".

- Turn ignition switch ON.

- Check DTC in "Self Diagnostic Result" mode of "BCM" using CONSULT.

Is DTC detected? YES >> Go to SEC-167, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to SEC-127, "Wiring Diagram".

1.CHECK FUSE

- Turn power switch OFF.

- Check that the following fuse in fuse block (J/B) is not blown.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace the blown fuse after repairing the affected circuit.

2.CHECK NATS ANTENNA AMP. POWER SUPPLY

- Disconnect NATS antenna amp. connector.

- Check voltage between NATS antenna amp. harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK NATS ANTENNA AMP. POWER SUPPLY CIRCUIT

- Disconnect fuse block (J/B) connector.

- Check continuity between fuse block (J/B) harness connector and NATS antenna amp. connector.

Is the inspection result normal? YES >> Replace fuse block (J/B).

NO >> Repair or replace harness.

4.CHECK NATS ANTENNA AMP. GROUND CIRCUIT

Check continuity between NATS antenna amp. harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace harness.

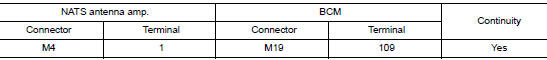

5.CHECK NATS ANTENNA AMP. COMMUNICATION SIGNAL 1

Check voltage signal between NATS antenna amp. harness connector and ground using an oscilloscope.

Is the inspection result normal? YES >> GO TO 7.

NO >> GO TO 6.

6.CHECK NATS ANTENNA AMP. OUTPUT SIGNAL CIRCUIT 1

- Disconnect BCM connector.

- Check continuity between NATS antenna amp. harness connector and BCM connector.

- Check continuity between NATS antenna amp. harness connector and ground.

Is the inspection result normal? YES >> GO TO 9.

NO >> Repair or replace harness.

7.CHECK NATS ANTENNA AMP. COMMUNICATION SIGNAL 2

Check voltage signal between NATS antenna amp. harness connector and ground using an oscilloscope.

Is the inspection result normal? YES >> Replace NATS antenna amp. Refer to SEC-192, "Removal and Installation".

NO >> GO TO 8.

8.CHECK NATS ANTENNA AMP. OUTPUT SIGNAL CIRCUIT 2

- Disconnect BCM connector.

- Check continuity between NATS antenna amp. harness connector and BCM connector.

- Check continuity between NATS antenna amp. harness connector and ground.

Is the inspection result normal? YES >> GO TO 9.

NO >> Repair or replace harness.

9.REPLACE BCM

- Replace BCM. Refer to BCS-135, "Removal and Installation".

- Perform initialization of BCM and registration of all keys using CONSULT.

>> Inspection End

B2557 VEHICLE SPEED

DTC Logic

DTC DETECTION LOGIC

NOTE:

- If DTC B2557 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to BCS-124, "DTC Logic".

- If DTC B2557 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to BCS-125, "DTC Logic".

|

DTC No. |

Trouble diagnosis name |

DTC detecting condition |

Possible cause |

| B2557 | VEHICLE SPEED | BCM detects one of the following conditions for 10

seconds continuously.

|

|

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

- Start engine and wait 10 seconds or more.

- Drive the vehicle at a vehicle speed of 10 km/h (6.2 MPH) or more for 10 seconds or more.

- Check DTC in тАЬSelf-Diagnostic ResultтАЭ mode of тАЬBCMтАЭ using CONSULT.

Is DTC detected? YES >> GO TO SEC-170, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

1.CHECK DTC OF тАЬABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)тАЭ

Check DTC in тАЬSelf-Diagnostic ResultтАЭ mode of тАЬABSтАЭ using CONSULT.

Is DTC detected? YES >> Perform the trouble diagnosis related to the detected DTC. Refer to BRC-55, "DTC Index".

NO >> GO TO 2.

2.CHECK DTC OF тАЬCOMBINATION METERтАЭ

Check DTC in тАЬSelf-Diagnostic ResultтАЭ mode of тАЬMETER/M&AтАЭ using CONSULT.

Is DTC detected? YES >> Perform the trouble diagnosis related to the detected DTC. Refer to MWI-30, "DTC Index".

NO >> GO TO 3.

3.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident" .

>> Inspection End.

B2602 SHIFT POSITION

DTC Logic

DTC DETECTION LOGIC

NOTE:

- If DTC B2602 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to BCS-124, "DTC Logic".

- If DTC B2602 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to BCS-125, "DTC Logic".

|

DTC No. |

Trouble diagnosis name |

DTC detecting condition |

Possible cause |

| B2602 | SHIFT POSITION | BCM detects the following status for 10 seconds.

|

|

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

- Start engine.

- Drive vehicle at a speed of 4 km/h (2.5 MPH) or more for 10 seconds or more.

- Check DTC in тАЬSelf-Diagnostic ResultтАЭ mode of тАЬBCMтАЭ using CONSULT.

Is DTC detected? YES >> Go to SEC-171, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to SEC-127, "Wiring Diagram".

1.CHECK CVT SHIFT SELECTOR SWITCH FUNCTION

- Turn ignition switch ON.

- Select тАЬDETE/CANCEL SWтАЭ and "VEH SPEED 1" in "Data Monitor" mode with CONSULT.

- Check тАЬDETE/CANCEL SWтАЭ and "VEH SPEED 1" indication under the following conditions.

Is the inspection result normal? YES >> Refer to GI-41, "Intermittent Incident".

NO-1 >> If DETE/CANCEL SW is incorrect. GO TO 4.

NO-2 >> If VEH SPEED 1 is incorrect. GO TO 2.

2.CHECK DTC OF COMBINATION METER

Check DTC in тАЬSelf-Diagnostic ResultтАЭ mode of тАЬMETER/M&AтАЭ using CONSULT.

Is DTC detected? YES >> Perform the trouble diagnosis related to the detected DTC. Refer to MWI-30, "DTC Index".

NO >> GO TO 3.

3.CHECK DTC OF ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

Check DTC in тАЬSelf-Diagnostic ResultтАЭ mode of тАЬABSтАЭ using CONSULT.

Is DTC detected? YES >> Perform the trouble diagnosis related to the detected DTC. Refer to BRC-55, "DTC Index".

NO >> GO TO 6.

4.CHECK CVT SHIFT SELECTOR CIRCUIT

- Disconnect BCM connector and CVT shift selector connector.

- Check continuity between CVT shift selector (park position switch) harness connector and BCM harness connector.

- Check continuity between CVT shift selector (park position switch) harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace harness.

5.CHECK CVT SHIFT SELECTOR CIRCUIT

- Disconnect BCM connector and CVT shift selector connector.

- Check continuity between CVT shift selector (park position switch) harness connector and BCM harness connector.

- Check continuity between CVT shift selector (park position switch) harness connector and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace harness.

6.CHECK CVT SHIFT SELECTOR (PARK POSITION SWITCH)

Refer to SEC-173, "Component Inspection".

Is the inspection result normal? YES >> GO TO 7.

NO >> Replace CVT shift selector. Refer to TM-194, "Removal and Installation".

7.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

>> Inspection End.

Component Inspection

1.CHECK CVT SHIFT SELECTOR (PARK POSITION SWITCH)

- Turn ignition switch OFF.

- Disconnect CVT shift selector connector.

- Check continuity between CVT shift selector (park position switch) terminals.

Is the inspection result normal? YES >> Inspection End.

NO >> Replace CVT shift selector. Refer to TM-194, "Removal and Installation".

B260F ENGINE STATUS

Description

BCM receives the engine status signal from ECM via CAN communication.

DTC Description

DTC DETECTION LOGIC

|

DTC No. |

CONSULT screen items (Trouble diagnosis content) |

DTC detecting condition |

| B260F | ENG STATE SIG LOST (Engine state signal lost) | BCM has not yet received the engine status signal from ECM when ignition switch is in the ON position. |

POSSIBLE CAUSE

- Harness or connectors (The CAN communication line is open or shorted.)

- ECM

FAIL-SAFE

Inhibit engine cranking

DTC CONFIRMATION PROCEDURE

1.CHECK DTC PRIORITY

If DTC B260F is displayed with DTC U1000 or U1010, first perform the trouble diagnosis for DTC U1000 or U1010.

Is applicable DTC detected? YES >> Perform diagnosis of applicable. U1000: Refer to BCS-124, "DTC Logic". U1010: Refer to BCS- 125, "DTC Logic".

NO >> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch ON and wait 2 seconds or more.

- Check DTC in тАЬSelf Diagnostic ResultтАЭ mode of тАЬBCMтАЭ using CONSULT.

Is DTC detected? YES >> Refer to SEC-174, "Diagnosis Procedure".

NO-1 >> To check malfunction symptom before repair: Refer to GI-41, "Intermittent Incident".

NO-2 >> Confirmation after repair: Inspection End.

Diagnosis Procedure

1.CHECK DTC PRIORITY

If DTC B260F is displayed with DTC U1000 or U1010, first perform the trouble diagnosis for DTC U1000 or U1010.

Is applicable DTC detected? YES >> Perform diagnosis of applicable. U1000: Refer to BCS-124, "DTC Logic". U1010: Refer to BCS- 125, "DTC Logic".

NO >> GO TO 2.

2.INSPECTION START

- Turn ignition switch ON.

- Select тАЬSelf Diagnostic ResultтАЭ mode of тАЬBCMтАЭ using CONSULT.

- Touch тАЬERASEтАЭ.

- Perform DTC CONFIRMATION PROCEDURE for DTC B260F. Refer to SEC-174, "DTC Description".

Is DTC detected? YES >> GO TO 3.

NO >> Inspection End.

3.REPLACE ECM

Replace ECM. Refer EC-499, "Removal and Installation".

>> Inspection End.

B261E VEHICLE TYPE

Description

There are two types of vehicles.

- HEV

- Conventional

DTC Logic

DTC DETECTION LOGIC

NOTE:

- If DTC B261E is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to BCS-124, "DTC Logic".

- If DTC B261E is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to BCS-125, "DTC Logic".

|

DTC No. |

Trouble diagnosis name |

DTC detecting condition |

Possible cause |

| B261E | VEHICLE TYPE | Difference of BCM configuration. |

|

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch ON under the following conditions.

- Shift selector lever is in the P (Park) or N (Neutral) position

- Do not depress brake pedal

- Check тАЬSelf-Diagnostic ResultтАЭ of "BCM" using CONSULT.

Is DTC detected? YES >> GO TO SEC-176, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

1.INSPECTION START

- Turn ignition switch ON.

- Check тАЬSelf-diagnostic resultтАЭ of "BCM" using CONSULT.

- Touch тАЬERASEтАЭ.

- Perform DTC Confirmation Procedure. Refer to SEC-176, "DTC Logic".

Is the 1st trip DTC B261E displayed again? YES >> GO TO 2.

NO >> Inspection End.

2.PERFORM BCM CONFIGURATION.

Perform the BCM configuration. Refer to BCS-121, "CONFIGURATION (BCM) : Work Procedure".

>> GO TO 3.

3.INSPECTION START

- Turn ignition switch ON.

- Check тАЬSelf-diagnostic resultтАЭ of "BCM" using CONSULT.

- Touch тАЬERASEтАЭ.

- Perform DTC Confirmation Procedure.

Refer to SEC-176, "DTC Logic".

Is the 1st trip DTC B261E displayed again? YES >> GO TO 4.

NO >> Inspection End.

4.CONFIRM ECM PART NUMBER.

Confirm the part number of the installed ECM is correct.

Is the ECM part number correct? YES >> Replace BCM. Refer to BCS-135, "Removal and Installation".

NO >> Replace ECM. Refer to EC-499, "Removal and Installation".

B27D1 START CUT RELAY OFF

DTC Logic

DTC DETECTION LOGIC

NOTE:

- If DTC B27D1 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to BCS-124, "DTC Logic".

- If DTC B27D1 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to BCS-125, "DTC Logic".

|

DTC No. |

Trouble diagnosis name |

DTC detecting condition |

Possible cause |

| B27D1 | STARTER CUT RELAY OFF | When comparing the starter cut relay signal (CAN) from IPDM E/R, BCM detects that starter cut relay is stuck in the OFF position for 1 second or more. |

|

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch under the following conditions to start engine,

and wait 1 second or more.

- Selector lever: In the P position

- Check DTC in "Self Diagnostic Result" mode of "BCM" using CONSULT.

Is DTC detected? YES >> Go to SEC-178, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to SEC-127, "Wiring Diagram".

1.CHECK STARTER CUT RELAY POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect starter cut relay.

- Check voltage between starter cut relay harness connector and ground.

Is the inspection result normal? YES >> GO TO 2.

NO-1 >> Check 30 A fusible link [M, located in the fuse block (J/B)].

NO-2 >> Check harness for open or short between starter cut relay and fusible link.

2.CHECK STARTER CUT RELAY CONTROL

- Reconnect starter cut relay.

- Check voltage between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK STARTER CUT RELAY CONTROL CIRCUIT

- Turn ignition switch OFF.

- Disconnect BCM connector.

- Disconnect starter cut relay.

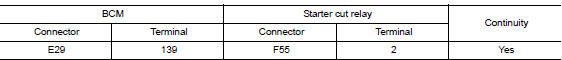

- Check continuity between BCM harness connector and starter cut relay harness connector.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK STARTER CUT RELAY CIRCUIT

- Turn ignition switch OFF.

- Disconnect IPDM E/R connector.

- Check continuity between IPDM E/R harness connector and starter cut relay harness connector.

- Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace harness.

5.CHECK STARTER CUT RELAY

Refer to SEC-180, "Component Inspection".

Is the inspection result normal? YES >> GO TO 6.

NO >> Replace starter cut relay.

6.REPLACE BCM

- Replace BCM. Refer to BCS-135, "Removal and Installation".

- Perform initialization of BCM and registration of all keys using CONSULT.

- Perform DTC CONFIRMATION PROCEDURE for DTC B27D1. Refer to SEC-178, "DTC Logic".

Is the inspection result normal? YES >> Inspection End.

NO >> Replace IPDM E/R. Refer to PCS-35, "Removal and Installation".

Component Inspection

1.CHECK STARTER CUT RELAY

- Turn ignition switch OFF.

- Disconnect starter cut relay.

- Check continuity between starter cut relay terminals.

Is the inspection result normal? YES >> Inspection End.

NO >> Replace starter cut relay.

B27D2 START CUT RELAY ON

DTC Logic

DTC DETECTION LOGIC

NOTE:

- If DTC B27D2 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to BCS-124, "DTC Logic".

- If DTC B27D2 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to BCS-125, "DTC Logic".

DTC CONFIRMATION PROCEDURE

|

DTC No. |

Trouble diagnosis name |

DTC detecting condition |

Possible cause |

| B27D2 | STARTER CUT RELAY ON | When comparing the starter cut relay signal (CAN) from IPDM E/R, BCM detects that starter cut relay is stuck in the ON position for 1 second or more. |

|

1.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch under the following conditions to start

engine, and wait 1 second or more.

- Selector lever: In the P position

- Check DTC in "Self Diagnostic Result" mode of "BCM" using CONSULT.

Is DTC detected? YES >> Go to SEC-181, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to SEC-127, "Wiring Diagram".

1.CHECK STARTER CUT RELAY POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect starter cut relay.

- Check voltage between starter cut relay harness connector and ground.

Is the inspection result normal? YES >> GO TO 2.

NO-1 >> Check 30 A fusible link [M, located in the fuse block (J/B)].

NO-2 >> Check harness for open or short between starter cut relay and fusible link.

2.CHECK STARTER CUT RELAY CONTROL

- Reconnect starter cut relay.

- Check voltage between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK STARTER CUT RELAY CONTROL CIRCUIT

- Turn ignition switch OFF.

- Disconnect BCM connector.

- Disconnect starter cut relay.

- Check continuity between BCM harness connector and starter cut relay harness connector.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK STARTER CUT RELAY CIRCUIT

- Turn ignition switch OFF.

- Disconnect IPDM E/R connector.

- Check continuity between IPDM E/R harness connector and starter cut relay harness connector.

- Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace harness.

5.CHECK STARTER CUT RELAY

Refer to SEC-183, "Component Inspection".

Is the inspection result normal? YES >> GO TO 6.

NO >> Replace starter cut relay.

6.REPLACE BCM

- Replace BCM. Refer to BCS-135, "Removal and Installation".

- Perform initialization of BCM and registration of all keys using CONSULT.

- Perform DTC CONFIRMATION PROCEDURE for DTC B27D2. Refer to SEC-181, "DTC Logic".

Is the inspection result normal? YES >> Inspection End.

NO >> Replace IPDM E/R. Refer to PCS-35, "Removal and Installation".

Component Inspection

1.CHECK STARTER CUT RELAY

- Turn ignition switch OFF.

- Disconnect starter cut relay.

- Check continuity between starter cut relay terminals.

Is the inspection result normal? YES >> Inspection End.

NO >> Replace starter cut relay.

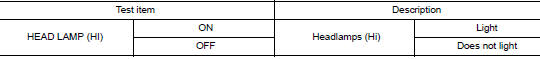

HEADLAMP FUNCTION

Component Function Check

1.CHECK FUNCTION

- Perform "HEAD LAMP(HI)" in "Active Test" mode of "THEFT ALM" of "BCM" using CONSULT.

- Check headlamps operation.

Is the inspection result normal? YES >> Inspection End.

NO >> Refer to SEC-184, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK HEADLAMP FUNCTION

Refer to SEC-184, "Component Function Check".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

2.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

>> Inspection End.

HOOD SWITCH

Component Function Check

1.CHECK FUNCTION

- Select "HOOD SW" in "Data Monitor" mode of "IPDM E/R" using CONSULT.

- Check "HOOD SW" indication under the following condition.

Is the indication normal? YES >> Hood switch is OK.

NO >> Go to SEC-185, "Diagnosis Procedure".

Diagnosis Procedure

Regarding Wiring Diagram information, refer to SEC-137, "Wiring Diagram".

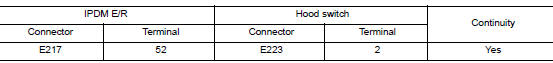

1.CHECK HOOD SWITCH SIGNAL CIRCUITS

- Turn ignition switch OFF.

- Disconnect hood switch connector.

- Check voltage between hood switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK HOOD SWITCH SIGNAL CIRCUITS

- Disconnect IPDM E/R connector.

- Check continuity between IPDM E/R harness connector and hood switch harness connector.

- Check continuity between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> Replace IPDM E/R. Refer to PCS-35, "Removal and Installation".

NO >> Repair or replace harness.

3.CHECK HOOD SWITCH GROUND CIRCUIT

Check continuity between hood switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK HOOD SWITCH

Refer to SEC-186, "Component Inspection" .

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace hood switch. Refer to DLK-370, "HOOD LOCK : Removal and Installation".

5.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

>> Inspection End.

Component Inspection

1.CHECK HOOD SWITCH

- Turn ignition switch OFF.

- Disconnect hood switch connector.

- Check continuity between hood switch terminals.

Is the inspection result normal? YES >> Inspection End.

NO >> Replace hood switch. Refer to DLK-370, "HOOD LOCK : Removal and Installation".

HORN FUNCTION

Component Function Check

1.CHECK FUNCTION 1

- Perform "VEHICLE SECURITY HORN" in "Active Test" mode of "THEFT ALM" of "BCM" using CONSULT.

- Check the horn operation.

Is the operation normal? YES >> Inspection End.

NO >> Go to SEC-137, "Wiring Diagram".

Component Inspection

1.CHECK ANTI-THEFT HORN RELAY

- Turn ignition switch OFF.

- Disconnect anti-theft horn relay.

- Check voltage between anti-theft horn relay terminal and ground under the following conditions.

Is the inspection result normal? YES >> Inspection End.

NO >> Replace anti-theft horn relay.

SECURITY INDICATOR LAMP

Component Function Check

1.CHECK FUNCTION

- Perform "THEFT IND" in "Active Test" mode of "IMMU" of "BCM" using CONSULT.

- Check security indicator lamp operation.

Is the inspection result normal? YES >> Inspection End.

NO >> Go to SEC-188, "Diagnosis Procedure".

Diagnosis Procedure

Regarding Wiring Diagram information, refer to SEC-137, "Wiring Diagram".

1.CHECK SECURITY INDICATOR LAMP POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect combination meter connector.

- Check voltage between combination meter harness connector and ground.

Is the inspection result normal? YES >> GO TO 2.

NO-1 >> Check 10 A fuse [No. 13, located in the fuse block (J/B)].

NO-2 >> Check harness for open or short between combination meter and fuse.

2.CHECK SECURITY INDICATOR LAMP SIGNAL

- Connect combination meter connector.

- Disconnect BCM connector.

- Check voltage between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 4.

3.REPLACE BCM

- Replace BCM. Refer to BCS-135, "Removal and Installation".

- Perform initialization of BCM and registration of all Intelligent Keys using CONSULT. Refer to the CONSULT Immobilizer mode and follow the on-screen instructions.

>> Inspection End.

4.CHECK SECURITY INDICATOR LAMP CIRCUIT

- Disconnect combination meter connector.

- Check continuity between combination meter harness connector and BCM harness connector.

- Check continuity between combination meter harness connector and ground.

Is the inspection result normal? YES >> Replace combination meter. Refer to MWI-82, "Removal and Installation".

NO >> Repair or replace harness.

Basic inspection

Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.GET INFORMATION FOR SYMPTOM

Get the detailed information from the customer about the symptom (the

condition and the ...

Symptom diagnosis

Symptom diagnosis

NISSAN VEHICLE IMMOBILIZER SYSTEM-NATS SYMPTOMS

Symptom Table

NOTE:

Before performing the diagnosis in the following table, check

тАЬSEC-150, "Work Flow"тАЭ.

Check tha ...

Other materials:

Preparation

Special Service Tool

The actual shape of the tools may differ from those illustrated here.

Tool number

(TechMate No.)

Tool name

Description

тАФ

(J-49286)

Drift and Pull gauge

Measuring drift and pull

Commercial Service Tool

Tool name

...

Meter control switch signal circuit

Diagnosis Procedure

Regarding Wiring Diagram information, refer to MWI-32, "Wiring Diagram".

1.CHECK METER CONTROL SWITCH SIGNAL

Turn ignition switch ON.

Check voltage between the following terminals of the meter control

switch harness connector M3.

Is the ins ...

Readiness for inspection/maintenance (I/M) test

WARNINGA vehicle equipped with All -Wheel Drive

(AWD) should never be tested using a two

wheel dynamometer (such as the dynamometers

used by some states for emissions

testing), or similar equipment. Make

sure you inform the test facility personnel

that your vehicle is equipp ...