Nissan Rogue Service Manual: Diagnosis and repair work flow

Work Flow

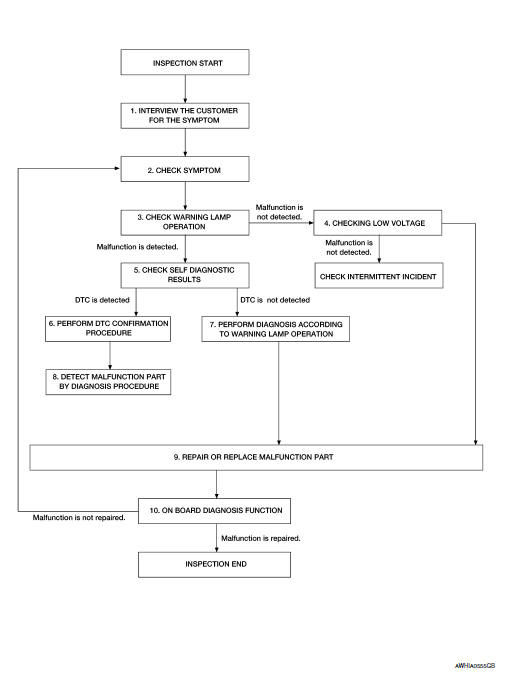

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW THE CUSTOMER FOR THE SYMPTOM

Interview the customer for the symptom (the condition and the environment when the incident/malfunction occurs).

>> GO TO 2.

2.CHECK SYMPTOM

Check the symptom from the customer information.

>> GO TO 3.

3.CHECK WARNING LAMP OPERATION

Check air bag warning lamp operation in the user mode.

Are any malfunction detected? YES >> GO TO 5.

NO >> GO TO 4.

4.CHECK LOW VOLTAGE

Check low voltage with CONSULT.

Are any malfunction detected? YES >> GO TO 9.

NO >> Check intermittent incident. Refer to GI-41, "Intermittent Incident".

5.CHECK SELF DIAGNOSTIC RESULTS

Check self diagnostic result with CONSULT or diagnosis mode.

If it is impossible to switch to diagnosis mode, follow the same procedure that DTC is not detected.

NOTE: Perform the following procedure if DTC is detected.

- Record DTC (Print them out with CONSULT.)

- Erase self diagnostic result.

- Study the relationship between the malfunction that DTC or air bag warning lamp indicates and the symptom that the customer describes.

- Check related service bulletins for information.

Is DTC detected? YES >> GO TO 6.

NO >> GO TO 7.

6.PERFORM DTC CONFIRMATION PROCEDURE

Perform DTC CONFIRMATION PROCEDURE for the DTC.

>> GO TO 8.

7.PERFORM DIAGNOSIS ACCORDING TO WARNING LAMP OPERATION

- Check air bag warning lamp operation in the user mode.

- Perform Diagnosis Procedure for the air bag warning lamp operation.

>> GO TO 9.

8.DETECT MALFUNCTIONING PART BY DIAGNOSTIC PROCEDURE

Inspect according to Diagnostic Procedure of the DTC.

>> GO TO 9.

9.REPAIR OR REPLACE THE MALFUNCTION PART

Repair or replace the malfunctioning part.

>> GO TO 10.

10.ON BOARD DIAGNOSIS FUNCTION

Check self diagnostic result and air bag warning lamp operation in the user mode.

Is the malfunction repaired? YES >> Inspection End.

NO >> GO TO 2.

Basic inspection

Basic inspection

...

Inspection and adjustment

Inspection and adjustment

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Description

When replacing the occupant classification system control unit, perform

zero point r ...

Other materials:

Preparation

Special Service Tool

The actual shape of the tools may differ from those illustrated here.

Tool number

(TechMate No.)

Tool name

Description

KV38100500

( — )

Drift

Installing sensor rotor

a: 80 mm (3.15 in) dia.

b: 60 mm (2.36 in) dia.

KV40 ...

Combination meter

Reference Value

VALUES ON THE DIAGNOSIS TOOL

*: DDS (hill descent control)

NOTE:

Some items are not available according to vehicle specification.

TERMINAL LAYOUT

PHYSICAL VALUES

Fail-safe

The combination meter activates the fail-safe control if the CAN

communica ...

P0196 EOT sensor

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0196

EOT SENSOR

(Engine oil temperature sensor range/performance)

A

Rationally incorrect voltage from the sensor is sent to ECM,

compared

...