Nissan Rogue Service Manual: Cooler pipe and hose

Exploded View

- Condenser

- High-pressure flexible hose

- Low-pressure flexible hose

- Low-pressure pipe

- Heating and cooling unit assembly

- High-pressure pipe

- Compressor

- O-ring

- Low-pressure service port

- High-pressure service port

LOW-PRESSURE PIP

LOW-PRESSURE PIPE : Removal and Installation

REMOVAL

- Discharge the refrigerant. Refer to HA-23, "Recycle Refrigerant".

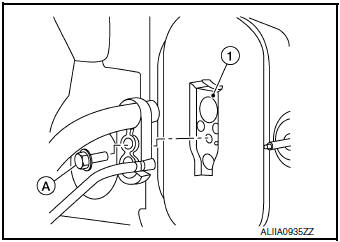

- Remove bolts (A) and engine upper mount (1).

- Remove the bolt (A) that retains the low-pressure flexible hose to the low-pressure pipe.

CAUTION: Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

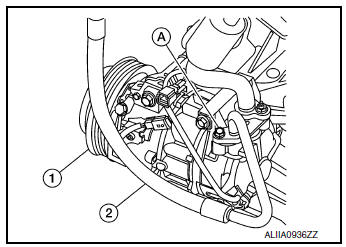

- Remove low-pressure pipe bracket bolts (A) and bracket.

- Release high-pressure pipe (2) from clamp (A).

- Remove nut (B) and low-pressure pipe (1).

- Remove the bolt (A) that retains the low-pressure and high-pressure pipe to the expansion valve (1).

- Remove low-pressure pipe.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Tighten bolts to specified torque. Refer to HA-32, "Exploded View".

- Do not reuse O-rings.

- Apply A/C oil to new O-rings for installation.

- After charging refrigerant, check for leaks. Refer to HA-21, "Leak Test".

LOW-PRESSURE FLEXIBLE HOSE

LOW-PRESSURE FLEXIBLE HOSE : Removal and Installation

REMOVAL

- Discharge the refrigerant. Refer to HA-23, "Recycle Refrigerant".

- Remove the bolt (A) that retains the low-pressure flexible hose to the low-pressure pipe.

CAUTION: Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

- Remove the nut (A) that retains the low-pressure flexible hose to the compressor.

- Remove the low-pressure flexible hose.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Tighten nut/bolt to specified torque. Refer to HA-32, "Exploded View".

- Do not reuse O-rings.

- Apply A/C oil to new O-rings for installation.

- After charging refrigerant, check for leaks. Refer to HA-21, "Leak Test".

HIGH-PRESSURE PIPE

HIGH-PRESSURE PIPE : Removal and Installation

REMOVAL

- Discharge the refrigerant. Refer to HA-23, "Recycle Refrigerant".

- Remove front bumper fascia. Refer to EXT-17, "Removal and Installation".

- Remove air duct assembly. Refer to EM-24, "Exploded View".

- Remove bolts (A) and upper engine mount (1).

- Release high-pressure pipe (2) from clamp (A).

(1): Low-pressure pipe

(B): Nut

- Remove bolt (A) that retains high-pressure pipe (1) to the condenser

(2).

CAUTION: Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

- Remove the bolt (A) that retains the high-pressure and low-pressure pipe to the expansion valve (1).

- Remove high-pressure pipe.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Tighten bolts to specified torque. Refer to HA-32, "Exploded View".

- Do not reuse O-rings.

- Apply A/C oil to new O-rings for installation.

- After charging the refrigerant, check for leaks. Refer to HA-21, "Leak Test".

HIGH-PRESSURE FLEXIBLE HOSE

HIGH-PRESSURE FLEXIBLE HOSE : Removal and Installation

REMOVAL

- Discharge the refrigerant. Refer to HA-23, "Recycle Refrigerant".

- Remove front bumper fascia. Refer to EXT-17, "Removal and Installation".

- Remove the bolt (A) that retains the high-pressure flexible hose (2) to the condenser (1).

CAUTION: Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

- Remove the bolt (A) that retains the high-pressure flexible hose (2) to the compressor (1).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Tighten bolts to specified torque. Refer to HA-37, "Exploded View".

- Do not reuse O-rings.

- Apply A/C oil to new O-rings for installation.

- After charging the refrigerant, check for leaks. Refer to HA-21, "Leak Test".

Compressor

Compressor

Exploded View

Compressor

Removal and Installation

REMOVAL

Discharge the refrigerant. Refer to HA-23, "Recycle Refrigerant".

Remove the engine under cover. Refer to EX ...

Condenser

Condenser

Exploded View

Air guide (LH)

Condenser upper bracket (LH)

Condenser (includes liquid tank)

Condenser upper bracket (RH)

Air guide (RH)

Refrigerant pressure sensor

C ...

Other materials:

System description

COMPONENT PARTS

Component Parts Location

No.

Component

Function

1

Combination meter

Combination meter transmits the vehicle speed signal to BCM via CAN

communication.

BCM also receives the vehicle speed signal from ABS actuator and

electric

...

Settings

The setting mode allows you to change the information

displayed in the vehicle information display:

Driver Assistance

Clock

Meter Settings

Vehicle Settings

Maintenance

Alarm

Tire Pressure

Unit

Language

Factory Reset

...

Removal and installation

NATS ANTENNA AMP.

Exploded View

Instrument finisher B

Push button ignition switch

NATS antenna amp.

Pawl

Removal and Installation

REMOVAL

Remove the instrument finisher B. Refer to IP-16, "INSTRUMENT

FINISHER B : Removal and Installation".

Release ...