Nissan Rogue Service Manual: Camshaft

Exploded View

- Camshaft position sensor (INT)

- O-ring

- Camshaft brackets (INT)

- Camshaft brackets (EXH)

- Camshaft (INT)

- O-ring

- Camshaft bracket (No. 1)

- Camshaft sprocket (INT)

- Front cover (partial view)

- Valve timing control cover O-rings (INT)

- Valve timing control cover

- Valve timing control solenoid valve O-rings

- Intake valve timing intermediate lock control solenoid valve

- Intake valve timing control solenoid valve

- Exhaust valve timing control solenoid valve

- Valve timing control cover O-rings (EXH)

- O-ring

- Camshaft sprocket (EXH)

- Cylinder head

- Camshaft (EXH)

- Signal plate (EXH)

- Signal plate (INT)

- Camshaft position sensor bracket

- Camshaft position sensor (EXH)

- Refer to INSTALLATION

Removal and Installation

REMOVAL

- Remove the rocker cover. Refer to EM-37, "Removal and Installation".

- Remove camshaft position sensors.

- Remove camshaft position sensor bracket.

- Remove the valve timing control cover. Refer to EM-75, "Valve Timing Control Cover".

- Set the No.1 cylinder at TDC on its compression stroke using the following procedure:

- Rotate crankshaft pulley clockwise, and align mating mark for

TDC (B) with timing indicator (A) on front cover, as shown.

NOTE: Do not use the white paint mark (C).

- At the same time, make sure that the mating marks (outer groove) (B) on camshaft sprockets are lined up with the pink links (A) in the timing chain, as shown.

- If not, rotate crankshaft pulley one more turn to line up the

mating marks (outer groove) (B) to the pink links (A), as

shown.

NOTE: Shown with front cover removed for illustration purposes only.

- Remove chain tensioner (1) and timing chain using the following procedure:

- Pull the lever (B) down and release the plunger stopper tab (C).

- Plunger stopper tab (C) can be pushed up to release (coaxial structure with lever (B)).

- Insert the stopper pin (A) into the tensioner body hole to hold

the

lever (B) and keep tab released.

NOTE: Allen wrench [2.5 mm (0.098)] is used for a stopper pin as an example.

- Insert plunger (C) into tensioner body by pressing timing chain slack guide (1).

- Keep timing chain slack (1) guide pressed and hold it by pushing the stopper pin (B) through the lever hole and body hole.

- Remove the chain tensioner bolts (A) and chain tensioner.

- Remove the timing chain from camshaft sprocket (INT) and camshaft sprocket (EXH).

CAUTION:

- Use suitable tool to prevent timing chain from falling into front cover after it has been removed from camshaft sprocket (INT) and camshaft sprocket (EXH).

- Do not rotate the crankshaft or camshafts while the timing chain is removed. It can cause damage to the valves and pistons.

- Remove the camshaft sprockets using the following procedure:

- Secure hexagonal part of the camshaft with a suitable tool and loosen the camshaft sprocket bolt.

- Remove the camshaft sprocket bolt and camshaft sprockets for both camshafts.

- Loosen the camshaft bracket bolts in the order as shown, and

remove the camshaft brackets and camshafts.

NOTE: Remove camshaft bracket (No. 1) by slightly tapping it with a rubber mallet.

(A) : Intake side

(B) : Exhaust side

: Engine front

: Engine front

- Remove the valve lifters.

NOTE: Check installation positions, and set them aside in the order removed.

INSPECTION AFTER REMOVAL

Camshaft Runout

- Put the camshaft on a V-block supporting the No.2 and No.5

journals.

CAUTION: Do not support the No. 1 journal (on the side of the camshaft sprocket) because it has different diameter from the other four locations.

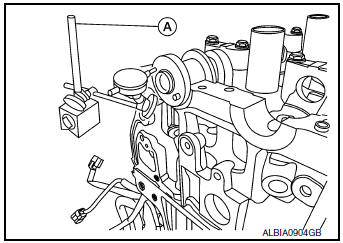

- Set suitable tool (A) vertically on the No.3 journal.

- Turn camshaft in one direction by hand, and measure the camshaft runout on the dial gauge total indicator reading.

Standard : Refer to EM-116, "Camshaft"

Camshaft Cam Height

- Measure the camshaft cam height using suitable tool (A).

Standard intake cam height : Refer to EM-116,

"Camshaft"

Standard exhaust cam height : Refer to EM-116,

"Camshaft"

- If wear is beyond the limit, replace the camshaft.

Camshaft Journal Clearance

Outer Diameter of Camshaft Journal

- Measure the outer diameter of the camshaft journal using suitable tool (A).

Standard No.1 outer diameter

: Refer to EM-116, "Camshaft"

Standard No.2, 3, 4, 5,

outer diameter

: Refer to EM-116, "Camshaft"

Inner Diameter of Camshaft Bracket

- Tighten the camshaft bracket bolts to the specified torque following the tightening pattern as shown.

Step 1 (bolts 9 - 11) : 1.96 N·m (0.20 kg-m, 17 in-lb)

Step 2 (bolts 1 - 8) : 1.96 N·m (0.20 kg-m, 17 in-lb)

Step 3 (bolts 1 - 11) : 5.88 N·m (0.60 kg-m, 52 in-lb)

Step 4 (bolts 1 - 11) : 10.41 N·m (1.1 kg-m, 8 ft-lb)

(A) : Intake side

(B) : Exhaust side

: Engine front

: Engine front

- Using suitable tool (A), measure inner diameter of camshaft bracket (1).

Standard

No.1

: Refer to EM-116, "Camshaft"

Standard

No.2, 3, 4, 5

: Refer to EM-116, "Camshaft"

Calculation of Camshaft Journal Clearance

- (Journal clearance) = (inner diameter of camshaft bracket) – (outer diameter of camshaft journal)

Standard : Refer to EM-116, "Camshaft"

- When out of the specified range above, replace either or both the

camshaft and the cylinder head assembly.

NOTE: Inner diameter of the camshaft bracket is manufactured together with the cylinder head. If the camshaft bracket is out of specification, replace the whole cylinder head assembly.

Camshaft End Play

- Install suitable tool (A) in the thrust direction on the front end of the camshaft. Measure the end play with the dial gauge while moving the camshaft forward and backward (in direction to axis).

Standard end play : Refer to EM-116, "Camshaft"

- Measure the following parts if out of the standard.

- Dimension (A) for camshaft No. 1 journal

Standard : Refer to EM-116, "Camshaft"

- Dimension (B) for cylinder head No. 1 journal

Standard : Refer to EM-116, "Camshaft"

- Standard : Refer to EM-116, "Camshaft"

Camshaft Sprocket Runout

- Install the camshaft in the cylinder head.

- Install the camshaft sprocket on the camshaft.

- Measure camshaft sprocket runout while turning the camshaft by hand using suitable tool (A).

Runout : Refer to EM-116, "Camshaft"

- If it exceeds the specification, replace camshaft sprocket.

Valve Lifter

- Check if the surface of the valve lifter has any excessive wear or cracks, replace as necessary.

Valve Lifter Clearance

Outer Diameter of Valve Lifter

- Measure the outer diameter of the valve lifter using suitable tool (A).

Valve lifter outer diameter : Refer to EM-116, "Camshaft"

- If out of the specified range, replace the valve lifter.

Valve Lifter Bore Inner Diameter

- Measure diameter of valve lifter bore of cylinder head using suitable tool (A).

Standard : Refer to EM-116, "Camshaft"

- If out of the specified range, replace the cylinder head assembly.

Calculation of Valve Lifter Clearance

- (Valve lifter clearance) = (hole diameter for valve lifter) – (outer diameter of valve lifter)

Standard : Refer to EM-116, "Camshaft"

- If out of specified range, replace either or both valve lifter and cylinder head assembly.

INSTALLATION

- Install the valve lifter.

- Install them in the same position from which they were removed.

- Install the camshafts.

(1) : Exhaust camshaft

(2) : Intake camshaft

NOTE: The distinction between the intake and exhaust camshafts is the difference in the shape of the rear.

- Install camshafts so that the dowel pins (A) on the front side are positioned as shown.

(1) : Intake camshaft

(2) : Exhaust camshaft

- Install camshaft brackets.

- Install by referring to identification mark on upper surface mark.

- Install so that identification mark can be correctly read when viewed from the exhaust side.

(A) : Intake side

(B) : Exhaust side

: Engine front

: Engine front

- Install camshaft bracket (No. 1) as follows.

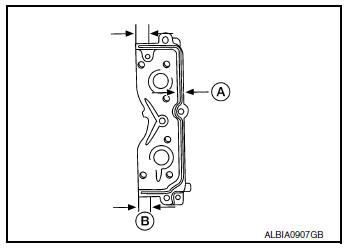

- Apply liquid gasket to camshaft bracket (No. 1) as shown (A), (B). Refer to EM-5, "Liquid Gasket".

- Apply liquid gasket to camshaft bracket (No. 1) contact surface on the front cover backside. Refer to EM-5, "Liquid Gasket"

(a) : 3.4 - 4.4 mm (0.134-0.173 in)

(1) : Front cover

- Apply liquid gasket to the outside of bolt hole on front cover.

Refer to EM-5, "Liquid Gasket"

- Position the camshaft bracket (No. 1) near the installation position, and install it without disturbing the liquid gasket applied to the surfaces.

(1) : Camshaft bracket (No. 1)

(2) : Front cover

- Tighten camshaft bracket bolts in four steps in the order as shown.

Step 1 (bolts 9 - 11) : 1.96 N·m (0.20 kg-m, 17 in-lb)

Step 2 (bolts 1 - 8) : 1.96 N·m (0.20 kg-m, 17 in-lb)

Step 3 (bolts 1 - 11) : 5.88 N·m (0.60 kg-m, 52 in-lb)

Step 4 (bolts 1 - 11) : 10.41 N·m (1.1 kg-m, 8 ft-lb)

(A) : Intake side

(B) : Exhaust side

: Engine front

: Engine front

CAUTION: After tightening camshaft bracket bolts, be sure to wipe off excessive liquid gasket from the parts listed below.

- Mating surface of rocker cover.

- Mating surface of front cover, when installed without the front cover.

- Install camshaft sprockets.

- Install them by lining up the mating marks (outer groove) (B) on each camshaft sprocket with the painted marks (A) on the timing chain during removal.

- Before installation of chain tensioner, it is possible to re-match the painted marks (A) on timing chain with the mating marks (B) on each sprocket.

CAUTION:

- Aligned mating marks could slip. Therefore, after matching them, hold the timing chain in place by hand.

- Before and after installing chain tensioner, check again to make sure that mating marks have not slipped.

- Install timing chain tension guide.

- Install chain tensioner using the following procedure:

- Install stopper pin (A) into the chain tensioner (1).

- Install the chain tensioner and pull the stopper pin out.

CAUTION: After installation, pull the stopper pin out, and make sure that the tensioner is fully released.

- Install intake valve timing control cover with the following procedure.

- Install intake valve timing intermediate lock control solenoid

valve, intake valve timing control solenoid

valve, and exhaust valve timing control solenoid valve to valve timing

control cover.

CAUTION: Do not reuse O-ring.

- Install O-ring to front cover side.

CAUTION: Do not reuse O-ring.

- Apply liquid gasket to the positions shown. Refer to GI-22, "Recommended Chemical Products and Sealants".

Diameter (A) : 3.4 - 4.4 mm (0.134 - 0.173 in)

- Install valve timing control cover.

- Tighten the bolts to specification in the numerical order as shown.

- Check and adjust valve clearances. Refer to EM-19, "Camshaft valve clearance".

- Install camshaft position sensor bracket.

- Apply liquid gasket to camshaft position sensor bracket as shown.

(A) : 2.0 - 3.0 mm (0.079-0.118)

(B) : 10.5 mm (0.413 in)

CAUTION:

- Use Genuine Silicone RTV Sealant, or equivalent. Refer to GI-22, "Recommended Chemical Products and Sealants".

- After installation be sure to wipe off excessive liquid gasket leaking from part (B).

- Installation should be done within 5 minutes after applying liquid gasket.

- Do not fill the engine with engine oil for at least 30 minutes after the components are installed to allow the liquid gasket to cure.

- Tighten bolts to specification in numerical order shown.

Camshaft position sensor bracket bolts : 10.41 N·m (1.1 kg-m, 8 ft-lb)

- Install the camshaft position sensors. Refer to EM-64, "Exploded View".

- Installation of the remaining components is in the reverse order of removal.

Inspection After Installation

Inspection of Camshaft Sprocket (INT) Oil Groove and Camshaft Sprocket (EXH) Oil Groove

WARNING: Check when engine is cold so as to prevent burns from any splashing engine oil.

CAUTION: Perform this inspection only when DTC P0011, P0014, P052A, P052B is detected in self-diagnostic results of CONSULT and it is directed according to inspection procedure of EC section.

- Check engine oil level and adjust oil level as necessary. Refer to LU-7, "Inspection".

- Remove the intake valve timing intermediate lock control solenoid valve, intake valve timing control solenoid valve, and exhaust valve timing control solenoid valve. Refer to EM-74, "Intake Valve Timing Intermediate Lock Control Solenoid Valve, Intake Valve Timing Control Solenoid Valve, and Exhaust Valve Timing Control Solenoid Valve".

- Perform the following procedure to prevent the engine from being unintentionally started while checking.

- Release fuel pressure. Refer to EC-144, "Work Procedure".

- Disconnect injector harness connectors.

- Crank engine, and then make sure that engine oil comes out of the valve timing control cover oil holes (A). End cranking after checking.

WARNING: Be careful not to touch rotating parts (drive belt, crankshaft pulley, etc.).

CAUTION:

- Engine oil may squirt from intake valve timing intermediate lock control solenoid valve, intake valve timing control solenoid valve, exhaust valve timing control solenoid valve installation holes during cranking. Use a shop cloth to prevent engine oil from splashing on worker, engine components and vehicle.

- Do not allow engine oil to get on rubber components such as

drive belts or engine mount insulators.

Immediately wipe off any splashed engine oil.

- If engine oil does not come out from valve timing control cover oil

holes (A), diagnose problem in lubrication

circuit such as dirty oil groove between oil strainer and intake valve

timing intermediate lock control

solenoid valve, intake valve timing control solenoid valve, or exhaust valve

timing control solenoid valve.

Refer to LU-5, "Engine Lubrication System".

- Remove components between intake valve timing intermediate lock control solenoid valve, intake valve timing control solenoid valve, exhaust valve timing control solenoid valve and camshaft sprocket (INT) or camshaft sprocket (EXH), (if necessary) and then check each oil groove for clogging.

- Clean oil groove if necessary. Refer to LU-5, "Engine Lubrication System".

- After inspection, install the remaining components in the reverse order of removal

Cylinder head

Cylinder head

Exploded View

Cylinder head

Cylinder head gasket

Refer to INSTALLATION

Removal and Installation

REMOVAL

Remove the timing chain. Refer to EM-45, "Removal and ...

Valve timing control

Valve timing control

Exploded View

Valve timing cover

2. O-rings

Intake valve timing intermediate

lock control solenoid valve

Intake valve timing control solenoid

valve

Exhaust valve timi ...

Other materials:

Connector Information

HOW TO USE CONNECTOR INFORMATION

Description

Number

Item

Description

1

Connector number

Alphabetic characters show to which harness the connector is

placed.

Numeric characters show the identification number of

connectors.

...

P0712 transmission fluid temperature sensor A

DTC Description

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P0712

FLUID TEMP SENSOR A

(Transmission Fluid Temperature Sensor A Circuit

Low)

When all of the following conditions are satisfied and this state is ...

Auto operation does not operate

MOONROOF

MOONROOF : Diagnosis Procedure

1. PERFORM INITIALIZATION PROCEDURE

Perform initialization procedure.

Refer to RF-24, "ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair

Requirement".

Is the inspection result normal?

YES >> Moonroof system is normal.

...