Nissan Rogue Service Manual: Basic inspection

COMPONENT INSPECTION

Inspection

AFTER A COLLISION

WARNING: Inspect all seat belt assemblies including retractors and attaching hardware after any collision.

NISSAN/INFINITI recommends that all seat belt assemblies in use during a collision be replaced unless the collision was minor and the belts show no damage and continue to operate properly. Failure to do so could result in serious personal injury in an accident. Seat belt assemblies not in use during a collision should also be replaced if either damage or improper operation is noted. Seat belt pretensioners should be replaced even if the seat belts are not in use during a frontal collision in which the air bags are deployed. Replace any seat belt assembly (including anchor bolts) if:

- The seat belt was in use at the time of a collision (except for minor collisions and the belts, retractors and buckles show no damage and continue to operate properly).

- The seat belt was damaged in an accident (i.e. torn webbing, bent retractor or guide, etc.).

- The seat belt attaching point is damaged in an accident. Inspect the seat belt attaching area for damage or distortion and repair if necessary before installing a new seat belt assembly.

- Anchor bolts are deformed or worn out.

- The seat belt pre-tensioner should be replaced even if the seat belts are not in use during the collision in which the air bags are deployed.

PRELIMINARY CHECKS

- Check the seat belt warning lamp for proper operation per the following:

- Turn ignition switch ON. The seat belt warning lamp should illuminate.

- Fasten driver seat belt. The seat belt warning lamp should turn OFF.

- If the air bag warning lamp is blinking, perform self-diagnosis

with CONSULT and air bag warning lamp.

Refer to SRC-18, "Trouble Diagnosis with CONSULT".

- Check that the seat belt retractor, seat belt anchor and buckle bolts are tightened firmly.

- Check the shoulder seat belt guide and shoulder belt height adjuster for front seats. Check that guide swivels freely and that webbing lays flat and does not bind in guide. Check that height adjuster operates properly and holds securely.

- Check retractor operation:

- Fully extend the seat belt webbing and check for twists, tears or other damage.

- Allow the seat belt to retract. Check that webbing returns smoothly and completely into the retractor. If the seat belt does not return smoothly, wipe the inside of the loops with a clean paper cloth. Dirt build-up in the loops of the upper anchors can cause the seat belts to retract slowly.

- Fasten the seat belt. Check that seat belt returns smoothly and completely to the retractor. If the webbing does not return smoothly, the cause may be an accumulation of dust or dirt. Use the “SEAT BELT TAPE SET” and perform the following steps.

- Inspect the front seat belt D-ring anchor

- Pull the seat belt out to a length of 500 mm (19.69 in) or more.

- Hold the seat belt at the center pillar webbing opening with a clip or other device.

- Pass a thin wire through the D-ring anchor webbing opening. Hold both ends of the wire and pull it tightly while moving it up and down several times along the webbing opening surface to remove dirt stuck there.

- Any dirt that cannot be removed with the wire can be removed by cleaning the opening with a clean cloth.

- Apply tape at the point where the webbing contacts the D-ring

anchor webbing opening.

NOTE: Apply the tape so that there is no slack or wrinkling.

- Remove the clip holding the seat belt and check that the webbing returns smoothly.

- Repeat steps above if necessary to check the other seat belts.

SEAT BELT RETRACTOR ON-VEHICLE CHECK

Emergency Locking Retractors (ELR) and Automatic Locking Retractors (ALR)

NOTE: All seat belt retractors are Emergency Locking Retractors (ELR) type. In an emergency (sudden stop) the retractor will lock and prevent the webbing from extending any further. All 3-point type seat belt retractors except the driver seat belt also have an Automatic Locking Retractors (ALR) mode. The ALR mode (also called child restraint mode) is used when installing child seats. The ALR mode is activated when the seat belt is fully extended. When the webbing is then retracted partially, the ALR mode automatically locks the seat belt in a specific position so the webbing cannot be extended any further. To cancel the ALR mode, allow the seat belt to fully wind back into the retractor.

Check the seat belt retractors with the following test(s) to determine if a retractor assembly is operating properly.

ELR Function Stationary Check

Grasp the shoulder webbing and pull forward quickly. The retractor should lock and prevent the belt from extending further

ALR Function Stationary Check

- Pull out the entire length of seat belt from retractor until a click is heard.

- Retract the webbing partially. A clicking noise should be heard as the webbing retracts, indicating that the retractor is in the Automatic Locking Retractors (ALR) mode.

- Grasp the seat belt and try to pull out the retractor. The webbing must lock and not extend any further. If it does not operate normally, replace the retractor assembly.

- Allow the entire length of the webbing to retract to cancel the automatic locking mode.

ELR Function Moving Check

WARNING: Perform the following test in a safe, open area clear of other vehicles and obstructions (for example, a large, empty parking lot). Road surface must be paved and dry. Do not perform the following test on wet or gravel roads or on public streets and highways. This could result in an accident and serious personal injury. The driver and passenger must be prepared to brace themselves in the event that the retractor does not lock.

- Fasten driver seat belt. Buckle a passenger into the seat for the belt that is to be tested

- Proceed to the designated safe area.

- Drive the vehicle at approximately 16 km/h (10 mph). Notify any passengers of a pending sudden stop and the driver and passenger must be prepared to brace themselves in the event that the retractor does not lock. Apply brakes firmly and make a very hard stop.

During stopping, seat belts should lock and not be extended. If the seat belt retractor assembly does not lock, perform the retractor off-vehicle check.

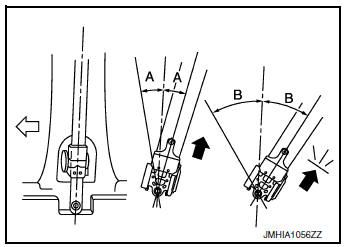

FRONT SEAT BELT RETRACTOR OFF-VEHICLE CHECK

- Remove the front seat belt retractor. Refer to SB-8, "SEAT BELT RETRACTOR : Removal and Installation".

- Slowly pull out webbing while tilting the seat belt retractor forward from the mounted position without twisting the seat belt retractor as shown.

- The webbing can be pulled out if the retractor is tilted 12° degree or less.

- The webbing can not be pulled out if the retractor is tilted 27°

degrees or more.

NOTE: A and B show tilting angles.

: Front

: Front

- Replace the seat belt retractor if it does not operate within specifications.

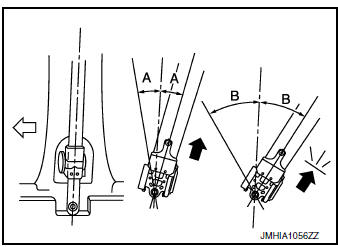

REAR SEAT BELT (LH/RH) RETRACTOR OFF-VEHICLE CHECK

- Remove the seat belt retractor. Refer to SB-12, "SEAT BELT RETRACTOR : Removal and Installation".

- Slowly pull out webbing while tilting the seat belt retractor forward from the mounted position without twisting the seat belt retractor as shown.

- The webbing can be pulled out if the retractor is tilted 12° degree or less.

- The webbing can not be pulled out if the retractor is tilted 27°

degrees or more.

NOTE: A and B show tilting angles.

: Front

: Front

- Replace the seat belt retractor if it does not operate within specifications.

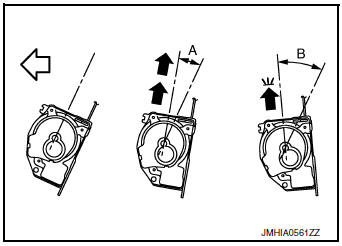

REAR SEAT BELT RETRACTOR (Center) OFF-VEHICLE CHECK

- Remove the seat belt retractor. Refer to SB-12, "SEAT BELT RETRACTOR : Removal and Installation".

- Slowly pull out webbing while tilting the seat belt retractor forward from the mounted position without twisting the seat belt retractor as shown.

- The webbing can be pulled out if the retractor is tilted 12° degree or less.

- The webbing can not be pulled out if the retractor is tilted 27°

degrees or more.

NOTE: A and B show tilting angles.

: Front

: Front

- Replace the seat belt retractor if it does not operate within specifications.

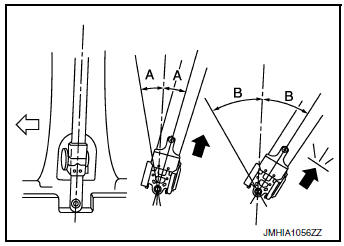

THIRD ROW SEAT BELT (LH/RH) RETRACTOR OFF-VEHICLE CHECK

- Remove the seat belt retractor. Refer to SB-17, "SEAT BELT RETRACTOR : Removal and Installation".

- Slowly pull out webbing while tilting the seat belt retractor forward from the mounted position without twisting the seat belt retractor as shown.

- The webbing can be pulled out if the retractor is tilted 12° degree or less.

- The webbing can not be pulled out if the retractor is tilted 27°

degrees or more.

NOTE: A and B show tilting angles.

: Front

: Front

- Replace the seat belt retractor if it does not operate within specifications.

Preparation

Preparation

Special Service Tool

The actual shape of the tools may differ from those illustrated here.

Tool number

(TechMate No.)

Tool name

Description

—

(J-46534)

Trim Tool Set ...

Other materials:

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

...

TCM

Exploded View

Bracket

Bracket

TCM

: Vehicle front

: N·m (kg-m, in-lb)

Removal and Installation

CAUTION:

Do not impact the TCM when removing or installing TCM.

When replacing TCM and transaxle assembly as a set, replace

transaxle assembly first and then

rep ...

System

CVT CONTROL SYSTEM

CVT CONTROL SYSTEM : System Description

SYSTEM DIAGRAM

MAIN CONTROL CONTENTS OF TCM

Controls

Reference

Line pressure control

TM-36, "LINE PRESSURE CONTROL : System Description"

Shift control

TM-37, "SHIFT CONTROL : System De ...